AUKOM 1

MODULES

1-1 Measurement quantities and units

1-2 2D and 3D coordinate systems

1-3 Coordinate measuring machines

1-4 Sensors of the coordinate measuring machine

1-5 Fundamentals of coordinate metrology

1-6 Dimensional tolerances

1-7 Geometric elements

1-8 Geometric relationships

1-9 Measurement preparation on a coordinate measuring machine

1-10 Sensor selection and qualification

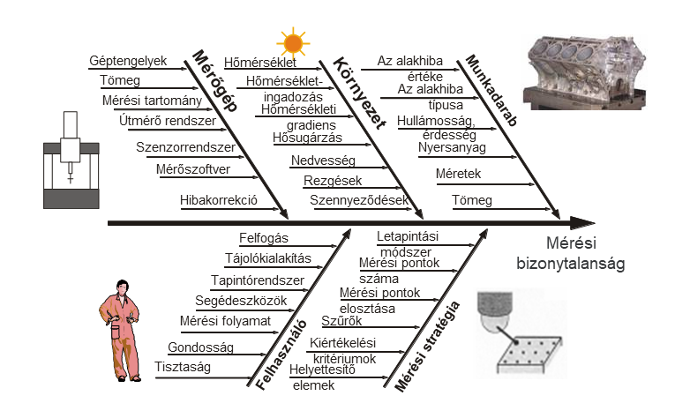

1-11 Measuring with a coordinate measuring machine

1-12 Measurement evaluation

1-13 Measurement planning

1-14 Documentation and quality management

AUKOM 1 offers fundamental knowledge for both beginner and advanced metrology professionals.

The term AUKOM is an acronym derived from AUsbildung KOordinatenMesstechnik, which means coordinate metrology training. It is a measurement technology education system independent of measuring machine manufacturers, globally recognized, with its certification internationally acknowledged. It was created within a three-year research project (1998-2001), which is continuously updated and modernized to meet the current requirements of the industry.

DURATION

4 days

NUMBER OF PARTICIPANTS

Max. 12 people

PREREQUISITES

None

EXAM

Yes

CERTIFICATE

Internationally accepted

LANGUAGE

Hungarian or English

INDUSTRY TARGET GROUP

Quality Assurance, Metrology, (Design, Development, Manufacturing)

OBJECTIVE

It establishes and reinforces industrial metrology fundamentals for both novice and experienced (primarily) metrology professionals

AUKOM 2

MODULES

2-1 Overview of the complete measurement process

2-2 Geometric overview

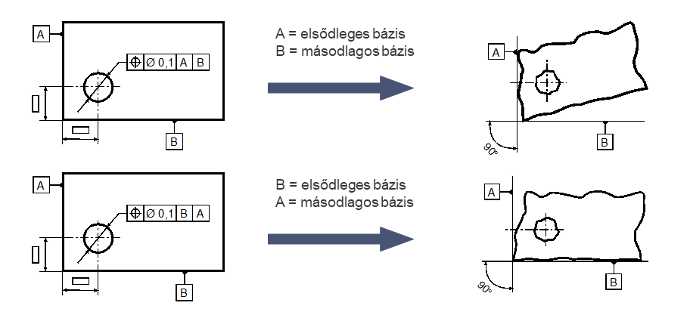

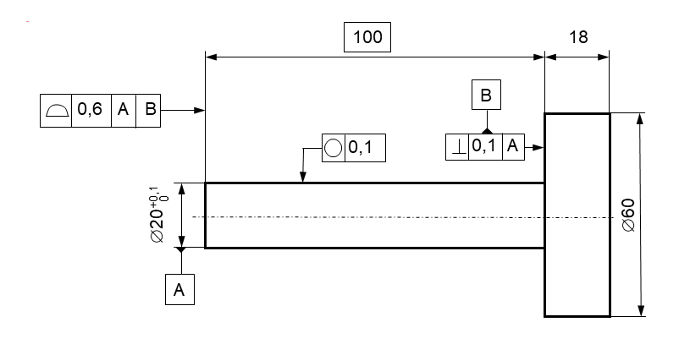

2-3 Form and position tolerances

2-4 Measurement strategy

2-5 Stylus sensors

2-6 Vision sensors

2-7 Distance measurement sensors

2-8 Computed tomography (Industrial CT process)

2-9 CNC programming

2-10 Measurement techniques for freeform surfaces

2-11 Measurement evaluation

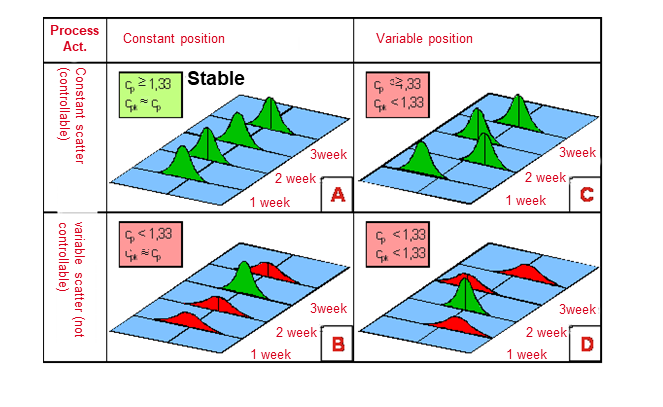

2-12 Factors influencing measurement results

2-13 Documentation

2-14 Culture of good measurements

AUKOM 2 provides advanced knowledge for trained metrology professionals.

The term AUKOM is an acronym derived from AUsbildung KOordinatenMesstechnik, which means coordinate metrology training. It is a measurement technology education system independent of measuring machine manufacturers, globally recognized, with its certification internationally acknowledged. It was created within a three-year research project (1998-2001), which is continuously updated and modernized to meet the current requirements of the industry.

DURATION

5 days

NUMBER OF PARTICIPANTS

Max. 12 people

PREREQUISITES

AUKOM 1 certificate is mandatory

EXAM

Yes

CERTIFICATE

Internationally accepted

LANGUAGE

Hungarian or English

INDUSTRY TARGET GROUP

Quality Assurance, Metrology, (Design, Development, Manufacturing)

OBJECTIVE

The training builds upon industrial metrology basics, offering deeper insights (primarily) for advanced metrology and quality assurance professionals

AUKOM GD&T

MODULES

1 Fundamentals of the ISO: Geometrical Product Specifications (GPS) system

2 Drawing symbols for form, orientation, position, and run-out tolerances

3 Form tolerances

4 Orientation, position, and run-out tolerances

5 Profile tolerances

6 Fundamentals of tolerancing I: dimensioning, the principle of independency, envelope requirement

7 Fundamentals of tolerancing II: maximum and minimum material condition, reciprocity requirement

8 Drawing symbols for form, orientation, position, and run-out tolerances – according to the ASME standard

9 Workshop (practical session)

The AUKOM GD&T course offers knowledge about drawing specifications for professionals in metrology, quality assurance, design, development, and manufacturing.

The term AUKOM is an acronym derived from AUsbildung KOordinatenMesstechnik, which means coordinate metrology training. It is a measurement technology education system independent of measuring machine manufacturers, globally recognized, with its certification internationally acknowledged. It was created within a three-year research project (1998-2001), which is continuously updated and modernized to meet the current requirements of the industry.

DURATION

3 days

NUMBER OF PARTICIPANTS

Max. 12 people

PREREQUISITES

None, but the AUKOM 1 and AUKOM 2 certificates are recommended

EXAM

No

CERTIFICATE

Internationally accepted

LANGUAGE

Hungarian or English

INDUSTRY TARGET GROUP

Quality Assurance, Metrology, Design, Development, Manufacturing

OBJECTIVE

The training aims to acquire expert knowledge of drawing specifications, with a special focus on form and position tolerances

AUKOM 3

MODULES

3-1 Basics - Geometry

3-2 Basics - Manufacturing technology

3-3 Basics - CAD

3-4 Point Cloud and Computer Tomography

3-5 Measuring programs

3-6 Digital Filtering and Evaluation

3-7 CMM Monitoring

3-8 Measuring Uncertainly and Process Capability

3-9 Quality Management

3-10 Process Monitoring

3-11 Inspection Room Management

AUKOM 3 provides expert-level knowledge for trained metrology professionals.

The term AUKOM is an acronym derived from AUsbildung KOordinatenMesstechnik, which means coordinate metrology training. It is a measurement technology education system independent of measuring machine manufacturers, globally recognized, with its certification internationally acknowledged. It was created within a three-year research project (1998-2001), which is continuously updated and modernized to meet the current requirements of the industry.

DURATION

5 days

NUMBER OF PARTICIPANTS

Max. 12 people

PREREQUISITES

AUKOM 1, AUKOM 2 and AUKOM GD&T certificates are mandatory

EXAM

Yes

CERTIFICATE

Internationally accepted

LANGUAGE

Hungarian or English, the course material is in English

INDUSTRY TARGET GROUP

Quality Assurance, Metrology

OBJECTIVE

The training builds on existing metrology knowledge, and it provides the most in-depth expertise for metrology and quality assurance professionals.